Our partner for research and development

The establishment of a production facility for bicycle carbon rims in Braunschweig is supported by

We are engineers and therefore led by the question, how to optimize manufacturing processes. We transfer our expertise from the aerospace sector to selected fields of mobility and sports: As an innovative company, we develop efficient solutions for new composite lightweight applications for our customers’ benefits.

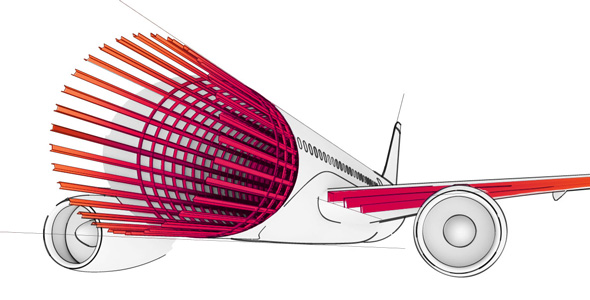

Lightweight structures gain in importance especially in the mobility sector: The lighter the aircrafts, ships and cars, the lower the fuel consumption and exhaust emission. Fibre composite components play a decisive role: FRP profiles replace metal profiles and are not only stronger than steel but also lighter than aluminium.

In practice: The aerospace sector — leading industry for lightweight construction — forecasts a 10 % reduction of CO2 emission through the use of carbon fibre for a current short-haul aircraft. (Source: Prof. Wiedemann, DLR). In the case of an average occupied 1500 km flight it results in about 5000 kg less CO2.

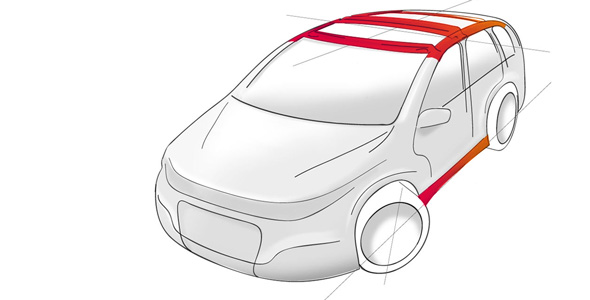

In the case of a traditional passenger car, 100 kg weight reduction means nearly 10 g less CO2 every 100 km. The structural use of carbon fibre enables the saving of 200 kg per car. Annualized, this represents 112 kg less CO2 for each average car. On a comparable scale, the electric power consumption and therefore emissions of an electric car can be lowered, and its reach increased.

Strong team and broad-minded partners are essential to make a strong product out of a good idea. Get in touch with us!

The tactical combination of material and manufacturing process is the key to product quality and cost efficiency. Our patented production process for preform profiles for RTM and other injection processes allows us to improve both simultaneously. The result: High quality at competitive price made in Germany.

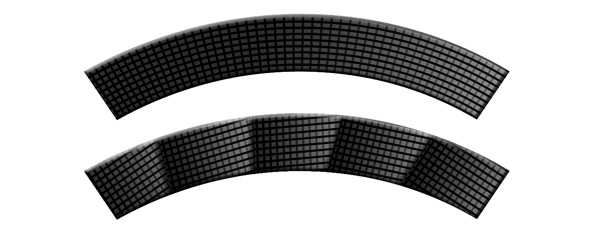

The patented COPRO® technology breaks new ground for composite lightweight applications. The use of non-crimp fabric bands leads to more strength and guarantees an improved load distribution in power flow direction. The uniform fibre orientation also provides a unique surface texture.

Featuring one single lap joint in each ply, we keep weight and resource consumption down to a minimum.

The adaption of the roll forming technology to the composite production is unprecedented and allows a multitude of possible profile geometries — open or closed — with variable curvature, width and cross section: for example beams, stringers and spars for aeronautics, door sills, rocker panels and roof or floor members for automotive as well as rims for the bicycle industry.

Mating rolls with variable rotating speed continuously shape the textile material in the final profile form. The simultaneous processing of multiple plies as well as the in-line integration of reinforcing plies and patches is possible. For hybrid applications, we can process glass, aramid or carbon fibre materials as well as metal bands simultaneously.

The patented COPRO® technology enables the industrial automation of the preforming process. By doing so, we can reduce the production time and costs by roughly 35 %. Furthermore, the automated manufacturing process guarantees constant high product quality.

The use of optical sensors for edge detection ensures a precise and controlled material flow. Contactless temperature sensors secure a uniform heating of the material. A special high-capacity fibre angle sensor enables the documentation and storage of the material orientation of each ply and warrant a complete quality control.

The COPRO® technology stands for process velocity and efficiency: The variable roll forming process reduces production costs by making the use of cost-intensive aluminium and steel tools for preforming obsolete. Moreover, we optimize the material utilization by working with prefabricated half goods, which means decreased cutting scrap.

Integrated in the RTM process chain and in combination with NCF material, the technology represents an attractive solution for the production of composite components. And it is compatible with every kind of infusion and injection process.

Sounds interesting? Just give us a call!

Our team of engineers and technicians provide a long-time experience in the production, design and construction of composite components and processes — and is always with passion and inventive talent out and about. We develop individual solutions for your composite profile production and integrate the COPRO® technology in your manufacturing process in collaboration with you.

Take advantage of the possibilities of our roll forming technology and save costs, time and resources within the manufacturing of your composite profiles.

Arne Stahl

Founder

Henrik Borgwardt

Founder and Managing Director

Production of composite profiles

You provide us with your requirements, and we produce your individual composite profiles at our manufacturing plant in Brunswick, Germany. We also produce pilot series for your process validation.

Process analysis and conception

We support you in the optimization of your fibre composite component production. Building on your requirements, we generate technical specifications, analyse the materials you currently use, provide advice on their processability with the COPRO® technology and design innovative concepts for your optimal, individual fibre composite profile solution.

Manufacturing facilities

We provide you with our technology and knowhow and take care about a smooth on-site integration of the COPRO® technology in your manufacturing process. In doing so, we are your partner from conception stage all the way to customer service and continuous improvement of your production process.

Strong team and broad-minded partners are essential to make a strong product out of a good idea. Get in touch with us!

The COPRO Technology GmbH has got its roots in the aerospace industry. From the first light bulb moment to the patent in 2012, a lot of time and energy went in the development of the COPRO® technology. Even though we are now entrepreneurs, we always keep our inventive spirit.

2008 | Eureka!

The idea of the COPRO® technology was born in 2008 within the framework of a diploma thesis — a paper about the first automated preforming facility for one sided curved H-beams. Our exploratory spirit was awakened, and we put our heart and soul into the research and development.

2012 | Test object: Airbus

In 2012, we got the opportunity to demonstrate our ability for the development of preforming processes — in fact on a weighty test object. Within the framework of a research project, we could apply our technology to the manufacturing of aircraft beams for the Airbus A350. In the project we really appreciated the collaboration with aerospace OEMs and suppliers, which helped generating requirements for the technology.

2012 | Innovation approved

Building on the crucial findings of the practical test, we kept enhancing our roll forming technology towards sensor-controlled complete automation with a proven record of success. Since 2012, the COPRO® technology is internationally patent-registered — a further milestone on our way. Cheers to the DLR, which supported us all along.

2015 | The step in the automotive industry

In 2015, the opportunity to adapt the COPRO® technology towards the automotive serial production arose. Alongside the DLR, we worked very closely with the BMW Group in order to broaden our field of application. This further practical experience brought us the multifaceted application possibilities of the technology to mind.

2016 | Ready for the market

In order to put the benefits of our technology into practice, we founded the COPRO Technology GmbH in 2016. Even though we are now entrepreneurs, our connection to the research persists — not least through the DLR as our partner for research and development by our side.

2019 | Our own production

We started the production of our first own product: the Lilienthal carbon fibre rim for mountain bikes.

Interested in getting to know us and our technology? Just give us a call!

How could we better demonstrate the suitability of the COPRO® technology than through the production of an own product? The Lilientha — a carbon fibre rim for mountain bikes — is the first product on the market, which is manufactured with the COPRO® technology. Understandable that we are full of pride.

Especially because we managed to realize a high-performance rim, which sets new standards regarding product quality in this sector: Improved load distribution, increased stability, reduced weight and a unique surface structure. As far as efficiency is concerned, the COPRO® technology also turned out to stand head and shoulders above conventional manufacturing processes. Less material and energy input provide a resource sparing and cost-efficient production.

With the Lilienthal, we managed to transfer our expertise from the aerospace sector into the bicycle industry: This is one of the reasons why Otto Lilienthal — German aerospace pioneer — gave his name to our rim.

COPRO Technology GmbH

Saarbrueckener Str. 254

38116 Braunschweig (Germany)

E-Mail: info@copro-technology.com

Vertretungsberechtigte Geschäftsführer: Henrik Borgwardt

Inhaltlich Verantwortliche: Henrik Borgwardt

Amtsgericht Braunschweig HRB 206183

USt.-ID: DE 309247998

COPRO Technology GmbH übernimmt keinerlei Gewähr für die Aktualität, Korrektheit, Vollständigkeit oder Qualität der bereitgestellten Informationen. Haftungsansprüche gegen COPRO Technology GmbH, welche sich auf Schäden materieller oder ideeller Art beziehen, die durch die Nutzung oder Nichtnutzung der dargebotenen Informationen bzw. durch die Nutzung fehlerhafter und unvollständiger Informationen verursacht wurden sind grundsätzlich ausgeschlossen, sofern seitens der COPRO Technology GmbH kein nachweislich vorsätzliches oder grob fahrlässiges Verschulden vorliegt. Alle Angebote sind freibleibend und unverbindlich. Der Autoren behalten es sich ausdrücklich vor, Teile der Seiten oder das gesamte Angebot ohne gesonderte Ankündigung zu verändern, zu ergänzen, zu löschen oder die Veröffentlichung zeitweise oder endgültig einzustellen.

Die Rechte an den dargestellten Fotos liegen bei der COPRO Technology GmbH. Weitergabe, Speichern, Kopieren und sonstiges Verwenden sind nur mit schriftlicher Genehmigung erlaubt. Dasselbe gilt für Grafiken, Objekte und Animationen jeder Art, falls nichts anderes angegeben ist. Sämtliche Inhalte, Bilder, Grafiken sind urheberrechtlich geschützt. Jede unerlaubte Nutzung wird zivil- und strafrechtlich verfolgt.

Privacy / DatenschutzDatenschutzerklärung

Stand: 08. Januar 2026

Inhaltsübersicht

Verantwortlicher

Henrik Borgwardt

COPRO Technology GmbH

Saarbrueckener Str. 254

38116 Braunschweig, Germany

Vertretungsberechtigte Personen: Henrik Borgwardt

E-Mail-Adresse: office@copro-technology.com

Telefon: +49 531 2834 1700

Impressum: www.copro-technology.com

Übersicht der Verarbeitungen

Die nachfolgende Übersicht fasst die Arten der verarbeiteten Daten und die Zwecke ihrer Verarbeitung zusammen und verweist auf die betroffenen Personen.

Arten der verarbeiteten Daten

Kategorien betroffener Personen

Zwecke der Verarbeitung

Maßgebliche Rechtsgrundlagen

Im Folgenden teilen wir die Rechtsgrundlagen der Datenschutzgrundverordnung (DSGVO), auf deren Basis wir die personenbezogenen Daten verarbeiten, mit. Bitte beachten Sie, dass zusätzlich zu den Regelungen der DSGVO die nationalen Datenschutzvorgaben in Ihrem bzw. unserem Wohn- und Sitzland gelten können.

Nationale Datenschutzregelungen in Deutschland: Zusätzlich zu den Datenschutzregelungen der Datenschutz-Grundverordnung gelten nationale Regelungen zum Datenschutz in Deutschland. Hierzu gehört insbesondere das Gesetz zum Schutz vor Missbrauch personenbezogener Daten bei der Datenverarbeitung (Bundesdatenschutzgesetz – BDSG). Das BDSG enthält insbesondere Spezialregelungen zum Recht auf Auskunft, zum Recht auf Löschung, zum Widerspruchsrecht, zur Verarbeitung besonderer Kategorien personenbezogener Daten, zur Verarbeitung für andere Zwecke und zur Übermittlung sowie automatisierten Entscheidungsfindung im Einzelfall einschließlich Profiling. Des Weiteren regelt es die Datenverarbeitung für Zwecke des Beschäftigungsverhältnisses (§ 26 BDSG), insbesondere im Hinblick auf die Begründung, Durchführung oder Beendigung von Beschäftigungsverhältnissen sowie die Einwilligung von Beschäftigten. Ferner können Landesdatenschutzgesetze der einzelnen Bundesländer zur Anwendung gelangen.

Nationale Datenschutzregelungen in Österreich: Zusätzlich zu den Datenschutzregelungen der Datenschutz-Grundverordnung gelten nationale Regelungen zum Datenschutz in Österreich. Hierzu gehört insbesondere das Bundesgesetz zum Schutz natürlicher Personen bei der Verarbeitung personenbezogener Daten (Datenschutzgesetz – DSG). Das Datenschutzgesetz enthält insbesondere Spezialregelungen zum Recht auf Auskunft, zum Recht auf Richtigstellung oder Löschung, zur Verarbeitung besonderer Kategorien personenbezogener Daten, zur Verarbeitung für andere Zwecke und zur Übermittlung sowie zur automatisierten Entscheidungsfindung im Einzelfall.

Nationale Datenschutzregelungen in der Schweiz: Zusätzlich zu den Datenschutzregelungen der Datenschutz-Grundverordnung gelten nationale Regelungen zum Datenschutz in der Schweiz. Hierzu gehört insbesondere das Bundesgesetz zum Datenschutz (DSG). Das DSG gilt insbesondere dann, wenn keine EU/EWG-Bürger betroffen sind und z.B. nur Daten von Schweizer Bürgern verarbeitet werden.

Übermittlung und Offenbarung von personenbezogenen Daten

Im Rahmen unserer Verarbeitung von personenbezogenen Daten kommt es vor, dass die Daten an andere Stellen, Unternehmen, rechtlich selbstständige Organisationseinheiten oder Personen übermittelt oder sie ihnen gegenüber offengelegt werden. Zu den Empfängern dieser Daten können z.B. Zahlungsinstitute im Rahmen von Zahlungsvorgängen, mit IT-Aufgaben beauftragte Dienstleister oder Anbieter von Diensten und Inhalten, die in eine Webseite eingebunden werden, gehören. In solchen Fall beachten wir die gesetzlichen Vorgaben und schließen insbesondere entsprechende Verträge bzw. Vereinbarungen, die dem Schutz Ihrer Daten dienen, mit den Empfängern Ihrer Daten ab.

Datenübermittlung innerhalb der Organisation: Wir können personenbezogene Daten an andere Stellen innerhalb unserer Organisation übermitteln oder ihnen den Zugriff auf diese Daten gewähren. Sofern diese Weitergabe zu administrativen Zwecken erfolgt, beruht die Weitergabe der Daten auf unseren berechtigten unternehmerischen und betriebswirtschaftlichen Interessen oder erfolgt, sofern sie Erfüllung unserer vertragsbezogenen Verpflichtungen erforderlich ist oder wenn eine Einwilligung der Betroffenen oder eine gesetzliche Erlaubnis vorliegt.

Einsatz von Cookies

Als "Cookies“ werden kleine Dateien bezeichnet, die auf Geräten der Nutzer gespeichert werden. Mittels Cookies können unterschiedliche Angaben gespeichert werden. Zu den Angaben können z.B. die Spracheinstellungen auf einer Webseite, der Loginstatus, ein Warenkorb oder die Stelle, an der ein Video geschaut wurde, gehören.

Cookies werden im Regelfall auch dann eingesetzt, wenn die Interessen eines Nutzers oder sein Verhalten (z.B. Betrachten bestimmter Inhalte, Nutzen von Funktionen etc.) auf einzelnen Webseiten in einem Nutzerprofil gespeichert werden. Solche Profile dienen dazu, den Nutzern z.B. Inhalte anzuzeigen, die ihren potentiellen Interessen entsprechen. Dieses Verfahren wird auch als "Tracking", d.h., Nachverfolgung der potentiellen Interessen der Nutzer bezeichnet. Zu dem Begriff der Cookies zählen wir ferner andere Technologien, die die gleichen Funktionen wie Cookies erfüllen (z.B., wenn Angaben der Nutzer anhand pseudonymer Onlinekennzeichnungen gespeichert werden, auch als "Nutzer-IDs" bezeichnet).

Soweit wir Cookies oder "Tracking"-Technologien einsetzen, informieren wir Sie gesondert in unserer Datenschutzerklärung.

Hinweise zu Rechtsgrundlagen: Auf welcher Rechtsgrundlage wir Ihre personenbezogenen Daten mit Hilfe von Cookies verarbeiten, hängt davon ab, ob wir Sie um eine Einwilligung bitten. Falls dies zutrifft und Sie in die Nutzung von Cookies einwilligen, ist die Rechtsgrundlage der Verarbeitung Ihrer Daten die erklärte Einwilligung. Andernfalls werden die mithilfe von Cookies verarbeiteten Daten auf Grundlage unserer berechtigten Interessen (z.B. an einem betriebswirtschaftlichen Betrieb unseres Onlineangebotes und dessen Verbesserung) verarbeitet oder, wenn der Einsatz von Cookies erforderlich ist, um unsere vertraglichen Verpflichtungen zu erfüllen.

Widerruf und Widerspruch (Opt-Out): Unabhängig davon, ob die Verarbeitung auf Grundlage einer Einwilligung oder gesetzlichen Erlaubnis erfolgt, haben Sie jederzeit die Möglichkeit, eine erteilte Einwilligung zu widerrufen oder der Verarbeitung Ihrer Daten durch Cookie-Technologien zu widersprechen (zusammenfassend als "Opt-Out" bezeichnet).

Sie können Ihren Widerspruch zunächst mittels der Einstellungen Ihres Browsers erklären, z.B., indem Sie die Nutzung von Cookies deaktivieren (wobei hierdurch auch die Funktionsfähigkeit unseres Onlineangebotes eingeschränkt werden kann).

Ein Widerspruch gegen den Einsatz von Cookies zu Zwecken des Onlinemarketings kann mittels einer Vielzahl von Diensten, vor allem im Fall des Trackings, über die US-amerikanische Seite http://www.aboutads.info/choices/ oder die EU-Seite http://www.youronlinechoices.com/ oder generell auf http://optout.aboutads.info erklärt werden.

Verarbeitung von Cookie-Daten auf Grundlage einer Einwilligung: Bevor wir Daten im Rahmen der Nutzung von Cookies verarbeiten oder verarbeiten lassen, bitten wir die Nutzer um eine jederzeit widerrufbare Einwilligung. Bevor die Einwilligung nicht ausgesprochen wurde, werden allenfalls Cookies eingesetzt, die für den Betrieb unseres Onlineangebotes erforderlich sind. Deren Einsatz erfolgt auf der Grundlage unseres Interesses und des Interesses der Nutzer an der erwarteten Funktionsfähigkeit unseres Onlineangebotes.

Kommerzielle und geschäftliche Leistungen

Wir verarbeiten Daten unserer Vertrags- und Geschäftspartner, z.B. Kunden und Interessenten (zusammenfassend bezeichnet als "Vertragspartner") im Rahmen von vertraglichen und vergleichbaren Rechtsverhältnissen sowie damit verbundenen Maßnahmen und im Rahmen der Kommunikation mit den Vertragspartnern (oder vorvertraglich), z.B., um Anfragen zu beantworten.

Diese Daten verarbeiten wir zur Erfüllung unserer vertraglichen Pflichten, zur Sicherung unserer Rechte und zu Zwecken der mit diesen Angaben einhergehenden Verwaltungsaufgaben sowie der unternehmerischen Organisation. Die Daten der Vertragspartner geben wir im Rahmen des geltenden Rechts nur insoweit an Dritte weiter, als dies zu den vorgenannten Zwecken oder zur Erfüllung gesetzlicher Pflichten erforderlich ist oder mit Einwilligung der Vertragspartner erfolgt (z.B. an beteiligte Telekommunikations-, Transport- und sonstige Hilfsdienste sowie Subunternehmer, Banken, Steuer- und Rechtsberater, Zahlungsdienstleister oder Steuerbehörden). Über weitere Verarbeitungsformen, z.B. zu Zwecken des Marketings, werden die Vertragspartner im Rahmen dieser Datenschutzerklärung informiert.

Welche Daten für die vorgenannten Zwecke erforderlich sind, teilen wir den Vertragspartnern vor oder im Rahmen der Datenerhebung, z.B. in Onlineformularen, durch besondere Kennzeichnung (z.B. Farben) bzw. Symbole (z.B. Sternchen o.ä.), oder persönlich mit.

Wir löschen die Daten nach Ablauf gesetzlicher Gewährleistungs- und vergleichbarer Pflichten, d.h., grundsätzlich nach Ablauf von 4 Jahren, es sei denn, dass die Daten in einem Kundenkonto gespeichert werden, z.B., solange sie aus gesetzlichen Gründen der Archivierung aufbewahrt werden müssen (z.B. für Steuerzwecke im Regelfall 10 Jahre). Daten, die uns im Rahmen eines Auftrags durch den Vertragspartner offengelegt wurden, löschen wir entsprechend den Vorgaben des Auftrags, grundsätzlich nach Ende des Auftrags.

Soweit wir zur Erbringung unserer Leistungen Drittanbieter oder Plattformen einsetzen, gelten im Verhältnis zwischen den Nutzern und den Anbietern die Geschäftsbedingungen und Datenschutzhinweise der jeweiligen Drittanbieter oder Plattformen.

Kontaktaufnahme

Bei der Kontaktaufnahme mit uns (z.B. per Kontaktformular, E-Mail, Telefon oder via soziale Medien) werden die Angaben der anfragenden Personen verarbeitet, soweit dies zur Beantwortung der Kontaktanfragen und etwaiger angefragter Maßnahmen erforderlich ist.

Die Beantwortung der Kontaktanfragen im Rahmen von vertraglichen oder vorvertraglichen Beziehungen erfolgt zur Erfüllung unserer vertraglichen Pflichten oder zur Beantwortung von (vor)vertraglichen Anfragen und im Übrigen auf Grundlage der berechtigten Interessen an der Beantwortung der Anfragen.

Bereitstellung des Onlineangebotes und Webhosting

Um unser Onlineangebot sicher und effizient bereitstellen zu können, nehmen wir die Leistungen von einem oder mehreren Webhosting-Anbietern in Anspruch, von deren Servern (bzw. von ihnen verwalteten Servern) das Onlineangebot abgerufen werden kann. Zu diesen Zwecken können wir Infrastruktur- und Plattformdienstleistungen, Rechenkapazität, Speicherplatz und Datenbankdienste sowie Sicherheitsleistungen und technische Wartungsleistungen in Anspruch nehmen.

Zu den im Rahmen der Bereitstellung des Hostingangebotes verarbeiteten Daten können alle die Nutzer unseres Onlineangebotes betreffenden Angaben gehören, die im Rahmen der Nutzung und der Kommunikation anfallen. Hierzu gehören regelmäßig die IP-Adresse, die notwendig ist, um die Inhalte von Onlineangeboten an Browser ausliefern zu können, und alle innerhalb unseres Onlineangebotes oder von Webseiten getätigten Eingaben.

E-Mail-Versand und -Hosting: Die von uns in Anspruch genommenen Webhosting-Leistungen umfassen ebenfalls den Versand, den Empfang sowie die Speicherung von E-Mails. Zu diesen Zwecken werden die Adressen der Empfänger sowie Absender als auch weitere Informationen betreffend den E-Mailversand (z.B. die beteiligten Provider) sowie die Inhalte der jeweiligen E-Mails verarbeitet. Die vorgenannten Daten können ferner zu Zwecken der Erkennung von SPAM verarbeitet werden. Wir bitten darum, zu beachten, dass E-Mails im Internet grundsätzlich nicht verschlüsselt versendet werden. Im Regelfall werden E-Mails zwar auf dem Transportweg verschlüsselt, aber (sofern kein sogenanntes Ende-zu-Ende-Verschlüsselungsverfahren eingesetzt wird) nicht auf den Servern, von denen sie abgesendet und empfangen werden. Wir können daher für den Übertragungsweg der E-Mails zwischen dem Absender und dem Empfang auf unserem Server keine Verantwortung übernehmen.

Erhebung von Zugriffsdaten und Logfiles: Wir selbst (bzw. unser Webhostinganbieter) erheben Daten zu jedem Zugriff auf den Server (sogenannte Serverlogfiles). Zu den Serverlogfiles können die Adresse und Name der abgerufenen Webseiten und Dateien, Datum und Uhrzeit des Abrufs, übertragene Datenmengen, Meldung über erfolgreichen Abruf, Browsertyp nebst Version, das Betriebssystem des Nutzers, Referrer URL (die zuvor besuchte Seite) und im Regelfall IP-Adressen und der anfragende Provider gehören.

Die Serverlogfiles können zum einen zu Zwecken der Sicherheit eingesetzt werden, z.B., um eine Überlastung der Server zu vermeiden (insbesondere im Fall von missbräuchlichen Angriffen, sogenannten DDoS-Attacken) und zum anderen, um die Auslastung der Server und ihre Stabilität sicherzustellen.

Eingesetzte Dienste und Diensteanbieter:

Cloud-Dienste

Wir nutzen über das Internet zugängliche und auf den Servern ihrer Anbieter ausgeführte Softwaredienste (sogenannte "Cloud-Dienste", auch bezeichnet als "Software as a Service") für die folgenden Zwecke: Dokumentenspeicherung und Verwaltung, Kalenderverwaltung, E-Mail-Versand, Tabellenkalkulationen und Präsentationen, Austausch von Dokumenten, Inhalten und Informationen mit bestimmten Empfängern oder Veröffentlichung von Webseiten, Formularen oder sonstigen Inhalten und Informationen sowie Chats und Teilnahme an Audio- und Videokonferenzen.

In diesem Rahmen können personenbezogenen Daten verarbeitet und auf den Servern der Anbieter gespeichert werden, soweit diese Bestandteil von Kommunikationsvorgängen mit uns sind oder von uns sonst, wie im Rahmen dieser Datenschutzerklärung dargelegt, verarbeitet werden. Zu diesen Daten können insbesondere Stammdaten und Kontaktdaten der Nutzer, Daten zu Vorgängen, Verträgen, sonstigen Prozessen und deren Inhalte gehören. Die Anbieter der Cloud-Dienste verarbeiten ferner Nutzungsdaten und Metadaten, die von ihnen zu Sicherheitszwecken und zur Serviceoptimierung verwendet werden.

Sofern wir mit Hilfe der Cloud-Dienste für andere Nutzer oder öffentlich zugängliche Webseiten Formulare o.a. Dokumente und Inhalte bereitstellen, können die Anbieter Cookies auf den Geräten der Nutzer für Zwecke der Webanalyse oder, um sich Einstellungen der Nutzer (z.B. im Fall der Mediensteuerung) zu merken, speichern.

Hinweise zu Rechtsgrundlagen: Sofern wir um eine Einwilligung in den Einsatz der Cloud-Dienste bitten, ist die Rechtsgrundlage der Verarbeitung die Einwilligung. Ferner kann deren Einsatz ein Bestandteil unserer (vor)vertraglichen Leistungen sein, sofern der Einsatz der Cloud-Dienste in diesem Rahmen vereinbart wurde. Ansonsten werden die Daten der Nutzer auf Grundlage unserer berechtigten Interessen (d.h., Interesse an effizienten und sicheren Verwaltungs- und Kollaborationsprozessen) verarbeitet

Eingesetzte Dienste und Diensteanbieter:

Onlinemarketing

Wir verarbeiten personenbezogene Daten zu Zwecken des Onlinemarketings, worunter insbesondere die Darstellung von werbenden und sonstigen Inhalten (zusammenfassend als "Inhalte" bezeichnet) anhand potentieller Interessen der Nutzer sowie die Messung ihrer Effektivität fallen.

Zu diesen Zwecken werden sogenannte Nutzerprofile angelegt und in einer Datei (sogenannte "Cookie") gespeichert oder ähnliche Verfahren genutzt, mittels derer die für die Darstellung der vorgenannten Inhalte relevante Angaben zum Nutzer gespeichert werden. Zu diesen Angaben können z.B. betrachtete Inhalte, besuchte Webseiten, genutzte Onlinenetzwerke, aber auch Kommunikationspartner und technische Angaben, wie der verwendete Browser, das verwendete Computersystem sowie Angaben zu Nutzungszeiten gehören. Sofern Nutzer in die Erhebung ihrer Standortdaten eingewilligt haben, können auch diese verarbeitet werden.

Es werden ebenfalls die IP-Adressen der Nutzer gespeichert. Jedoch nutzen wir IP-Masking-Verfahren (d.h., Pseudonymisierung durch Kürzung der IP-Adresse) zum Schutz der Nutzer. Generell werden im Rahmen des Onlinemarketingverfahren keine Klardaten der Nutzer (wie z.B. E-Mail-Adressen oder Namen) gespeichert, sondern Pseudonyme. D.h., wir als auch die Anbieter der Onlinemarketingverfahren kennen nicht die tatsächlich Identität der Nutzer, sondern nur die in deren Profilen gespeicherten Angaben.

Die Angaben in den Profilen werden im Regelfall in den Cookies oder mittels ähnlicher Verfahren gespeichert. Diese Cookies können später generell auch auf anderen Webseiten die dasselbe Onlinemarketingverfahren einsetzen, ausgelesen und zu Zwecken der Darstellung von Inhalten analysiert als auch mit weiteren Daten ergänzt und auf dem Server des Onlinemarketingverfahrensanbieters gespeichert werden.

Ausnahmsweise können Klardaten den Profilen zugeordnet werden. Das ist der Fall, wenn die Nutzer z.B. Mitglieder eines sozialen Netzwerks sind, dessen Onlinemarketingverfahren wir einsetzen und das Netzwerk die Profile der Nutzer im den vorgenannten Angaben verbindet. Wir bitten darum, zu beachten, dass Nutzer mit den Anbietern zusätzliche Abreden, z.B. durch Einwilligung im Rahmen der Registrierung, treffen können.

Wir erhalten grundsätzlich nur Zugang zu zusammengefassten Informationen über den Erfolg unserer Werbeanzeigen. Jedoch können wir im Rahmen sogenannter Konversionsmessungen prüfen, welche unserer Onlinemarketingverfahren zu einer sogenannten Konversion geführt haben, d.h. z.B., zu einem Vertragsschluss mit uns. Die Konversionsmessung wird alleine zur Analyse des Erfolgs unserer Marketingmaßnahmen verwendet.

Hinweise zu Rechtsgrundlagen: Sofern wir die Nutzer um deren Einwilligung in den Einsatz der Drittanbieter bitten, ist die Rechtsgrundlage der Verarbeitung von Daten die Einwilligung. Ansonsten werden die Daten der Nutzer auf Grundlage unserer berechtigten Interessen (d.h. Interesse an effizienten, wirtschaftlichen und empfängerfreundlichen Leistungen) verarbeitet. In diesem Zusammenhang möchten wir Sie auch auf die Informationen zur Verwendung von Cookies in dieser Datenschutzerklärung hinweisen.

Eingesetzte Dienste und Diensteanbieter:

Präsenzen in sozialen Netzwerken

Wir unterhalten Onlinepräsenzen innerhalb sozialer Netzwerke, um mit den dort aktiven Nutzern zu kommunizieren oder um dort Informationen über uns anzubieten.

Wir weisen darauf hin, dass dabei Daten der Nutzer außerhalb des Raumes der Europäischen Union verarbeitet werden können. Hierdurch können sich für die Nutzer Risiken ergeben, weil so z.B. die Durchsetzung der Rechte der Nutzer erschwert werden könnte. Im Hinblick auf US-Anbieter, die unter dem Privacy-Shield zertifiziert sind oder vergleichbare Garantien eines sicheren Datenschutzniveaus bieten, weisen wir darauf hin, dass sie sich damit verpflichten, die Datenschutzstandards der EU einzuhalten.

Ferner werden die Daten der Nutzer innerhalb sozialer Netzwerke im Regelfall für Marktforschungs- und Werbezwecke verarbeitet. So können z.B. anhand des Nutzungsverhaltens und sich daraus ergebender Interessen der Nutzer Nutzungsprofile erstellt werden. Die Nutzungsprofile können wiederum verwendet werden, um z.B. Werbeanzeigen innerhalb und außerhalb der Netzwerke zu schalten, die mutmaßlich den Interessen der Nutzer entsprechen. Zu diesen Zwecken werden im Regelfall Cookies auf den Rechnern der Nutzer gespeichert, in denen das Nutzungsverhalten und die Interessen der Nutzer gespeichert werden. Ferner können in den Nutzungsprofilen auch Daten unabhängig der von den Nutzern verwendeten Geräte gespeichert werden (insbesondere, wenn die Nutzer Mitglieder der jeweiligen Plattformen sind und bei diesen eingeloggt sind).

Für eine detaillierte Darstellung der jeweiligen Verarbeitungsformen und der Widerspruchsmöglichkeiten (Opt-Out) verweisen wir auf die Datenschutzerklärungen und Angaben der Betreiber der jeweiligen Netzwerke.

Auch im Fall von Auskunftsanfragen und der Geltendmachung von Betroffenenrechten weisen wir darauf hin, dass diese am effektivsten bei den Anbietern geltend gemacht werden können. Nur die Anbieter haben jeweils Zugriff auf die Daten der Nutzer und können direkt entsprechende Maßnahmen ergreifen und Auskünfte geben. Sollten Sie dennoch Hilfe benötigen, dann können Sie sich an uns wenden.

Eingesetzte Dienste und Diensteanbieter:

Planung, Organisation und Hilfswerkzeuge

Wir setzen Dienstleistungen, Plattformen und Software anderer Anbieter (nachfolgend bezeichnet als "Drittanbieter”) zu Zwecken der Organisation, Verwaltung, Planung sowie Erbringung unserer Leistungen ein. Bei der Auswahl der Drittanbieter und ihrer Leistungen beachten wir die gesetzlichen Vorgaben.

In diesem Rahmen können personenbezogenen Daten verarbeitet und auf den Servern der Drittanbieter gespeichert werden. Hiervon können diverse Daten betroffen sein, die wir entsprechend dieser Datenschutzerklärung verarbeiten. Zu diesen Daten können insbesondere Stammdaten und Kontaktdaten der Nutzer, Daten zu Vorgängen, Verträgen, sonstigen Prozessen und deren Inhalte gehören.

Sofern Nutzer im Rahmen der Kommunikation, von Geschäfts- oder anderen Beziehungen mit uns auf die Drittanbieter bzw. deren Software oder Plattformen verwiesen werden, können die Drittanbieter Nutzungsdaten und Metadaten zu Sicherheitszwecken, zur Serviceoptimierung oder zu Marketingzwecken verarbeiten. Wir bitten daher darum, die Datenschutzhinweise der jeweiligen Drittanbieter zu beachten.

Hinweise zu Rechtsgrundlagen: Sofern wir die Nutzer um deren Einwilligung in den Einsatz der Drittanbieter bitten, ist die Rechtsgrundlage der Verarbeitung von Daten die Einwilligung. Ferner kann deren Einsatz ein Bestandteil unserer (vor)vertraglichen Leistungen sein, sofern der Einsatz der Drittanbieter in diesem Rahmen vereinbart wurde. Ansonsten werden die Daten der Nutzer auf Grundlage unserer berechtigten Interessen (d.h. Interesse an effizienten, wirtschaftlichen und empfängerfreundlichen Leistungen) verarbeitet. In diesem Zusammenhang möchten wir Sie auch auf die Informationen zur Verwendung von Cookies in dieser Datenschutzerklärung hinweisen.

Eingesetzte Dienste und Diensteanbieter:

Löschung von Daten

Die von uns verarbeiteten Daten werden nach Maßgabe der gesetzlichen Vorgaben gelöscht, sobald deren zur Verarbeitung erlaubten Einwilligungen widerrufen werden oder sonstige Erlaubnisse entfallen (z.B., wenn der Zweck der Verarbeitung dieser Daten entfallen ist oder sie für den Zweck nicht erforderlich sind).

Sofern die Daten nicht gelöscht werden, weil sie für andere und gesetzlich zulässige Zwecke erforderlich sind, wird deren Verarbeitung auf diese Zwecke beschränkt. D.h., die Daten werden gesperrt und nicht für andere Zwecke verarbeitet. Das gilt z.B. für Daten, die aus handels- oder steuerrechtlichen Gründen aufbewahrt werden müssen oder deren Speicherung zur Geltendmachung, Ausübung oder Verteidigung von Rechtsansprüchen oder zum Schutz der Rechte einer anderen natürlichen oder juristischen Person erforderlich ist.

Weitere Hinweise zu der Löschung von personenbezogenen Daten können ferner im Rahmen der einzelnen Datenschutzhinweise dieser Datenschutzerklärung erfolgen.

Änderung und Aktualisierung der Datenschutzerklärung

Wir bitten Sie, sich regelmäßig über den Inhalt unserer Datenschutzerklärung zu informieren. Wir passen die Datenschutzerklärung an, sobald die Änderungen der von uns durchgeführten Datenverarbeitungen dies erforderlich machen. Wir informieren Sie, sobald durch die Änderungen eine Mitwirkungshandlung Ihrerseits (z.B. Einwilligung) oder eine sonstige individuelle Benachrichtigung erforderlich wird.